Automated racks and conveyors

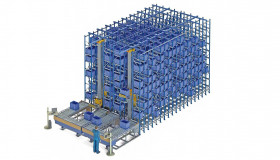

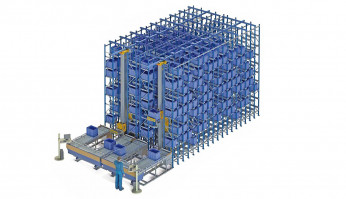

It is used for automated storage of cargo on pallets. The main advantage is the ability to quickly access each storage location.

- Use of useful warehouse capacity: 80-90%

- An ability to store a wide range of products

- Accessibility to any pallet

- Use of useful warehouse capacity: 90%

- The channel depth is not limited

- Shuttle travel speed: 0.8-1 m/s

- Use of useful warehouse capacity: 70-90%

- The channel depth is not limited

- Shuttle travel speed: 0.8-1 m/s

- Maximum level of automation

- Use of useful warehouse capacity: 75-85%

- Operating temperature: -35 °C to +35 °C

- Work on FIFO and LIFO principles

- Significant acceleration of the warehouse operation

- Operating mode: Continuous

- Accuracy of operations: 99.99%

- Eliminates the loss of time on operations

- Working space height is up to 45 m

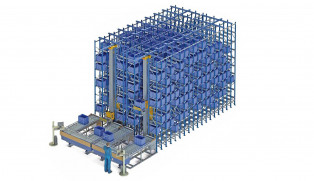

Will be useful in the complex automation of the warehouse with products in boxes. Reduce the cost of moving goods inside the warehouse and increase the speed of its processing.

- Speed: 2 to 4 m/s

- High accuracy of operations

- Simplicity and convenience in operation and maintenance

- Safe operation of the rack system

- System height: up to 25 m

- Speed: 2 to 4 m/s

- The minimum operating temperature is -35 ° C

- No errors related to the "human factor"

Modula is a modern solution for automatic storage systems. Helps reduce storage space by halving while maintaining a wide range of products.

- Capacity: up to 80 tons

- Height: 3.3 to 16.1 m

- Maximum efficient use of warehouse space

- Automated control system

- Fully automatic lifting/lowering

- Integration into the warehouse management system

- Up to 90% space saving

- Possibility of use as part of conveyor

- Save up to 90% of space

- Width: 130 or 170 cm

- Shelf load capacity is up to 200 kg

- Touch controls

- They are suitable for small parts, products and spare parts

- Maximum compact storage

- Installation time is no more than 48 hours

- Height is up to 7 meters

- Capacity: up to 80 tons

- Height: 3 300 to 16 100 mm

- Maximum efficient use of warehouse space

- Perfect accuracy of complete set

Growing demands for speed and reliability in order preparation, especially in areas such as online sales, require solutions to meet these needs.

- Complete set productivity: up to 350 lines per hour

- Operating temperature range: -30°C to +50 °C

- Integration with WMS

- Easy to use

- Maximum crate weight: up to 50 kg

- It is suitable for plastic containers and corrugated cardboard

- It is adaptable to containers of any size

- Reduces a significant number of errors

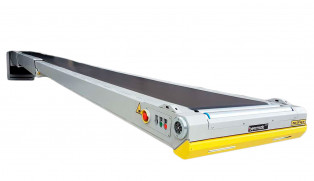

The efficiency of production largely depends on the availability of conveyor and / or sorting system. They reduce the time to transport the goods inside the warehouse and increase its productivity.

- Automation of transportation of finished products and raw materials

- They are suitable for "cold" warehouses and refrigerators

- They are compatible with pallets of all sizes

- Carrying capacity is up to 2000 kg

- We can use them in cold storage and freezing warehouses

- They are compatible with most types of containers

- Maximum crate weight is 50 kg

- High processing speed

- They facilitate loading and unloading of goods

- They extend two-four times when unfolded

- Maximum load: 80 kg/m

- High mobility and flexibility of use

- Efficient use of space

- Continuous movement of goods

- Maximum load: up to 100 kg/m2

- They accelerate loading and unloading operations

- They easily adapt to the required length and height

- Maximum extension: up to 18 m

- The speed of cargo movement is 0.8 m/s

- Sorting speed: up to 15 000 units/hour

- Accurate product identification system

- Additional options available

- The speed of goods movement is up to 3 m/s

Robotization of the warehouse will eliminate the influence of the human factor and speed up work. Together with the elements of automation, the work is able to significantly optimize internal logistics.

- High speed and accuracy of work

- Various types of grips are possible

- Speed – up to 10 cycles / min.

- Operation in fully automatic mode

- Load capacity: up to 1 500 kg depending on the model

- Possibility of continuous operation

- Safety systems of the highest category

- Automatic systems for transportation and movement, loading/unloading

- Load capacity: up to 700 kg

- 24/7 operation mode

- Safety systems of the highest category

- It increases the density of inventory

- It eliminates difficult routine

- It complies with the safety standard EN ISO 3691-4:2000

The field of automated equipment is quite complex in technical terms (design, installation and assembly work, settings), so we do not leave our customers alone with the equipment, and offer to use our services.

A pallet wrapper is an automated device for wrapping products in film. This device significantly speeds up the packaging process and simplifies the work of warehouse employees.

- High mobility

- Autonomy of work up to 150 pallets

- Have digital control panel

- Flexible

- Budget model

- Touch control panel

- Wide range of models

- Reliable and functional model

- Attractive price

- Suitable for wrapping and moving the pallet

- Ultra-fast

- High capacity

- Wide range of additional features

Automation is a long-term investment, a source of competitive advantage for manufacturers, distributors and retailers. It helps increase productivity, minimize manual labor and reduce errors.

The Sklad Service team consists of experts with 17 years of experience in the field of warehousing logistics, which gives us the opportunity to generate the best Smart-solutions for automation of storage systems.