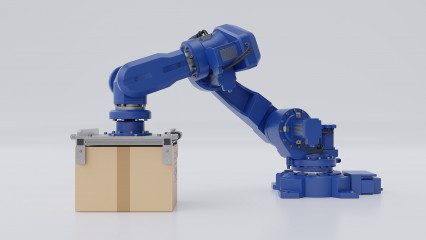

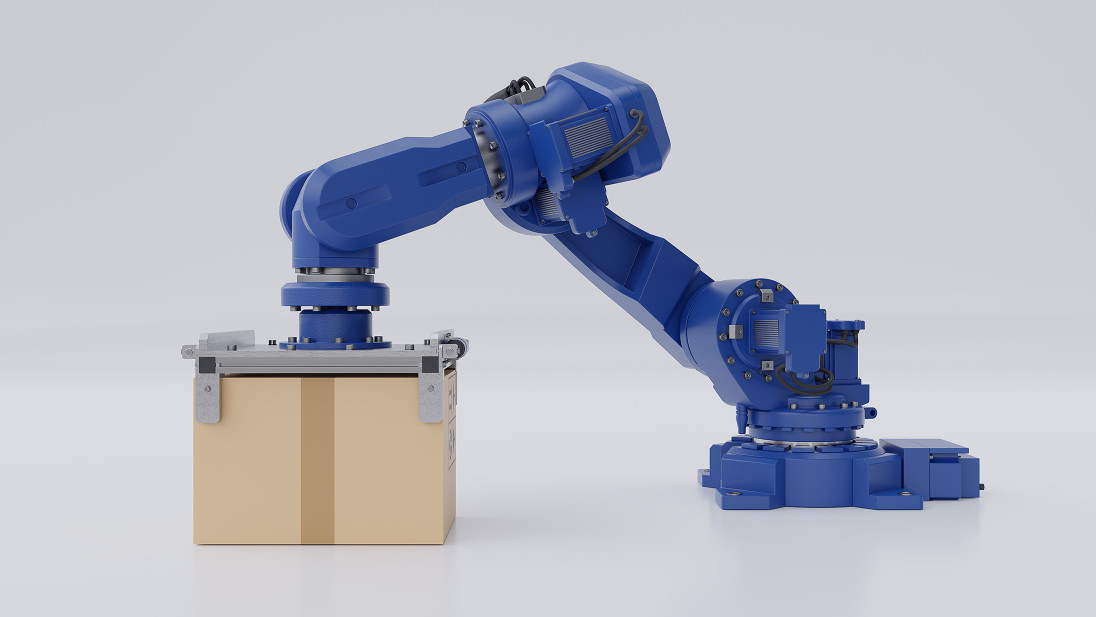

Industrial robots

- High speed and accuracy of work

- Various types of grips are possible

- Speed – up to 10 cycles / min.

Video

Purpose

Industrial robots are designed to automatically perform various operations with goods and raw materials (loading/unloading, picking, wrapping, labelling, packaging), and serve as part of a production line for welding, painting, assembly, etc. The high speed and precision of the robots ensures maximum productivity, consistently high output and cost-efficient manual labour.

Suitable for

- Piece goods

- Boxes

- Crates

Spheres of activity

-

DIY (construction, repair)

-

Food, beverages

-

Drogerie (cosmetics, household products)

-

HoReCa, catering

-

Clothing, shoes

-

Pharmaceuticals, medicine

-

Household appliances, electronics

-

Agro-industrial complex, forestry

-

Cars, special-purpose machineries

-

Education, culture, printing industry

-

Sports, tourism, entertainment

Description

An industrial robot (manipulator) is a multifunctional machine with up to 14 controllable rotating elements with the possibility of programming for a wide range of tasks. The most popular types of industrial robots include linear (Cartesian), articulated, parallel (Delta) and SCARA robots.

The design of warehouse terminals and the choice of suitable robotized equipment should be based on an approximate useful load, types of operations, a number of axes of rotation (degrees of freedom) and a radius of action. Each of the manipulators described above has advantages and disadvantages.

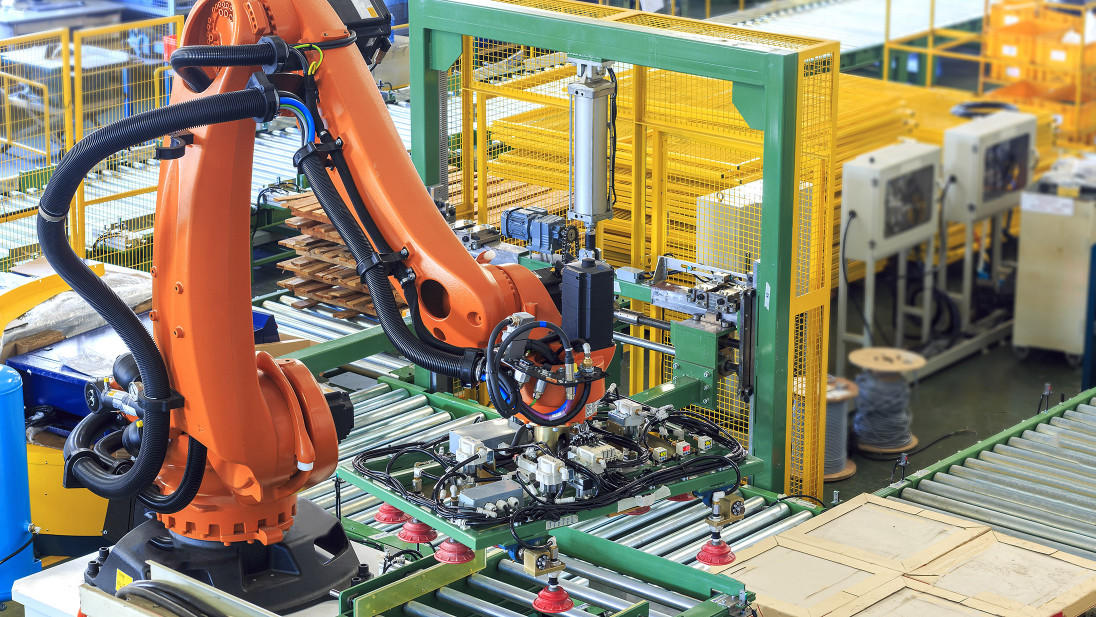

Articulated systems are the most versatile and multifunctional. Their large number of axes of rotation and high load capacity allow them to perform incredibly complex operations even in confined spaces, bypassing possible obstacles. Disadvantages of articulated robots are that they have a limited range of motion, programming complexity and high cost (from 60 to 140 thousand euros).

Linear robots have a high range of action and one to four degrees of freedom. They are relatively easy to programme and provide the highest accuracy of operations. These systems are used during loading and unloading and production operations.

SCARA robots typically have no more than four axes of rotation and are used for relatively simple operations in a limited space. Their tasks include reloading, stacking, assembly, and packaging. These units are considered the most affordable among all types of industrial robots.

Parallel robots are used for precise assembly and packaging of lightweight items in food, pharmaceutical and electronics industries. Systems of this type offer high speed and precision.

Perhaps no modern production line is possible without the use of industrial robots. These automation devices not only guarantee consistently high quality of work, but also help to achieve maximum productivity. Please contact the specialists of Sklad Service to place an order for the supply of robotized systems. You will receive favourable terms of cooperation, official warranty service and possibility of obtaining equipment in any region of Ukraine.

Specifications

Additional files

for your tasks

With 18 years of experience, we have created a list of effective solutions to problems in any area of business.

We will help to create the most effective structure for your tasks.

Terms of delivery

The price for this type of product depends on the exchange rate, may be higher or lower, subject to clarification. Also, the price depends on the set of additional components you have chosen and the color of the product.

Please note that prices are calculated individually depending on the volume of the order. For wholesale buyers there is a flexible system of discounts.

Large and non-standard orders are discussed on an individual basis.

The company employs a professional logistics department. We cooperate only with reliable carriers and guarantee high-quality delivery according to the agreed terms. Pickup from our warehouse in Kyiv is also possible.

We cooperate with legal entities and individuals, we accept payments in any convenient form.

The amount of prepayment is agreed in each case.

By our own efforts and those of our partners, we are involved in the production process of each of our products, products and services. The presence of production of warehouse racks allows us to significantly optimize production costs and provide our customers with only the best prices.

The production is equipped with advanced equipment, thanks to which we produce the required amount of products in the shortest possible time, as well as – successfully implement projects of any complexity, with any type of required racking structures.

The price for this type of product depends on the exchange rate, may be higher or lower, subject to clarification. Also, the price depends on the set of additional components you have chosen and the color of the product.

Please note that prices are calculated individually depending on the volume of the order. For wholesale buyers there is a flexible system of discounts.

Large and non-standard orders are discussed on an individual basis.

The company employs a professional logistics department. We cooperate only with reliable carriers and guarantee high-quality delivery according to the agreed terms. Pickup from our warehouse in Kyiv is also possible.

We cooperate with legal entities and individuals, we accept payments in any convenient form.

The amount of prepayment is agreed in each case.

By our own efforts and those of our partners, we are involved in the production process of each of our products, products and services. The presence of production of warehouse racks allows us to significantly optimize production costs and provide our customers with only the best prices.

The production is equipped with advanced equipment, thanks to which we produce the required amount of products in the shortest possible time, as well as – successfully implement projects of any complexity, with any type of required racking structures.