Our services

Regardless of the industry you are in, Sklad Service will provide you with a range of unique storage solutions.

We will help you find services for your business

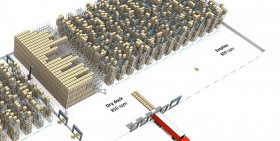

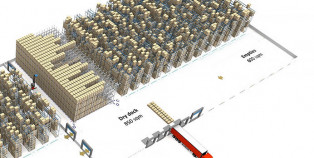

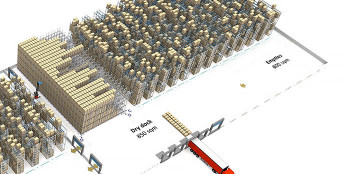

Warehouse automation services

Warehouse automation services

Warehouse automation is a set of technologies, methods and systems that allow you to control and improve the operations of the warehouse using various automated devices, scanners, robots and software.

- Analyzes logistics flows by functional zones

- Describes existing logistics flows, identifies bottlenecks and losses

- Generates potential options for optimization solutions

- Expert opinion on audit results

- Process verification and integration with the information system

- Optimizes inbound and outbound logistics processes

- Compacts the areas of the corresponding warehouse zones

- Provides variability of solutions and outlines their sequence

- Reduces the amount of cash resources frozen in stocks

- Allows you to reduce storage space

- Allows you to correctly manage inventory flows

- Optimizes the use of equipment, machinery, and personnel

- Verification of solutions offered to the customer and the feasibility of their application

- Identifying shortcomings in the existing management system

- Inventory analytics, process performance assessment

Loading equipment maintenance services

Loading equipment maintenance services

Buying loaders is only part of the matter, knowing how to inspect and maintenance is another. Trust those who do it every day.

- Detects malfunctions in advance

- Eliminates unexpected expenses

- Supports the functionality of the equipment

- Provides minimal equipment downtime

- Diagnoses breakdowns

- Fixes technical problems

- Does not distract equipment from operation for a long time

- Ensures correct tire disassembly and installation

- It does not distract the equipment from the workflow for a long time

- Improves the operational qualities of equipment

- Speeds up the process of delivering equipment to the customer

- It has a guarantee of operational operability

- Minimizes cash costs

- Optimizes cash flows and deductions

- The equipment has been working for you since the transaction was concluded

- Registration and insurance payments are included in the lease payment

Maintenance of racking systems

Maintenance of racking systems

Serviced (scheduled) technical inspection and timely repair of rack systems is a mandatory step to ensure trouble-free and continuous operation of the warehouse, which in the future will reduce the likelihood of stopping operational processes to a minimum.

- Checking the stability, evenness and integrity of structures

- Ensuring that elements are fixed in compliance with the operating rules

- Providing recommendations for the repair and replacement of structural elements

- Expert conclusion on the results of the audit (review)

- Examination of the integrity of racking elements

- Providing recommendations for the repair and replacement of structural elements

- Providing new structural elements

- Dismantling and installation works, fixing in compliance with the operating rules

- Technical inspection of racks, warehouse facility audit

- Careful dismantling of racking systems

- Transportation to a new location

- Installation and fixing of structural elements in compliance with the operating rules

- Checking the suitability for further use of structures

- Ensuring that elements are fixed in compliance with the operating rules

- Formation of options for repair and replacement of structural elements