Storage in crates and per item

- Speed: 2 to 4 m/s

- High accuracy of operations

- Simplicity and convenience in operation and maintenance

- Safe operation of the rack system

- System height: up to 25 m

- Speed: 2 to 4 m/s

- The minimum operating temperature is -35 ° C

- No errors related to the "human factor"

The pace of market development requires equipping the warehouse with the most efficient and economical solutions to ensure storage in boxes and individually. Gravity shelving, shuttles and AS / RS systems help to solve such issues. We know how with the help of storage systems in boxes and individually you can structure goods with a wide range, automate their movement, increase the rotation of goods and all this with the rational use of storage space.

Gravity racks for storage of goods in boxes.

Gravity shelf racks are structurally represented by shelves with a slope to the horizon. Thanks to the principle of "first in, first out" box, installed on the loading side, moves independently towards the selection.

Gravity racks are used in warehouses with high turnover. In addition, Warehouse Service Kyiv has the opportunity to complete gravity racks by implementing additional automated systems, such as Pick-to-light.

Gravity shelf racks are designed to work in temperatures of -20 to +40, with a maximum weight of the box (box) of 50 kg and are suitable for plastic containers and corrugated cardboard.

Storage in boxes: the benefits of using shuttle racks.

Shuttle systems for boxes are used for storage and movement of boxes weighing up to 35 kg with a speed of 2 to 4 m / s. Such systems allow you to reduce the load on staff by moving boxes or boxes to the desired cell automatically. One operator is enough to service one rack array. The movement of the shuttle (trolleys) is carried out by means of the built-in electric drives for which rechargeable batteries are provided. This solution avoids additional difficulties associated with the operation of other types of power plants. Due to the flexibility of the system, the shuttle can serve both one and several levels.

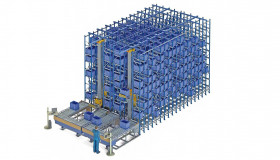

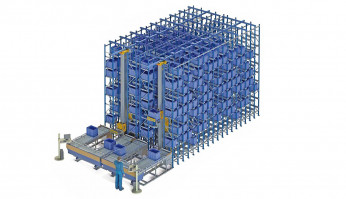

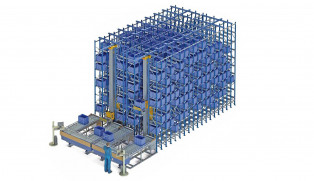

Advantages of the AS / RS system for boxes.

The height of the systems is 25 meters, which ensures the most efficient use of the warehouse area - the capacity can be increased 1.5 - 2 times without reconstruction of the building. Full automation is the advantage of such systems over shuttle. However, there is an option for manual control of the stacker crane. By the way, it requires a smaller working corridor than diesel or electric forklifts with a driver. High speed of the crane-stacker, and also the increased height of storage, a guarantee of effective work of warehouses with big commodity flows.

Warehouse Service specialists adapt the project to any size of boxes, pallets, boxes and other types of containers. These systems can be used in both conventional and low-temperature warehouses. The proposed storage systems in boxes have a wide range of options, thereby increasing their versatility and the ability to mount in warehouses of different industries.

Sklad Service offers a wide range of solutions for storage of goods in boxes, delivers and installs various storage systems in any locality of Ukraine.