Conveyor and sorting systems

- Automation of transportation of finished products and raw materials

- They are suitable for "cold" warehouses and refrigerators

- They are compatible with pallets of all sizes

- Carrying capacity is up to 2000 kg

- We can use them in cold storage and freezing warehouses

- They are compatible with most types of containers

- Maximum crate weight is 50 kg

- High processing speed

- They facilitate loading and unloading of goods

- They extend two-four times when unfolded

- Maximum load: 80 kg/m

- High mobility and flexibility of use

- Efficient use of space

- Continuous movement of goods

- Maximum load: up to 100 kg/m2

- They accelerate loading and unloading operations

- They easily adapt to the required length and height

- Maximum extension: up to 18 m

- The speed of cargo movement is 0.8 m/s

- Sorting speed: up to 15 000 units/hour

- Accurate product identification system

- Additional options available

- The speed of goods movement is up to 3 m/s

Conveyor and sorting systems.

The optimal functioning of the modern warehouse is based on reducing the amount of manual labor. This is due to the need to fulfill orders as accurately and in a short time. That is why the interest of market players in the automation of logistics processes is so high. One of the types of automation of the logistics process in the warehouse are conveyor systems. Therefore, many manufacturers of transport and lifting equipment have focused on the production of conveyors. Conveyor production in Ukraine is represented by both manufacturers of ready-made solutions and components.

Conveyor equipment facilitates or completely replaces logistics operations performed by employees. The conveyor system not only increases the accuracy of ordering, but also reduces the time spent on moving goods within the warehouse complex. The advantages of conveyor lines are: high reliability; reduction of energy consumption; simplicity of construction and its operation; maintaining a high rate of cargo turnover. This makes the production of conveyors relevant.

Warehouse Service Kyiv offers the following solutions for optimizing the logistics processes of your business: conveyor systems for pallets, conveyor systems for boxes and crates, flexible conveyor systems, spiral conveyors and combined systems.

Conveyor systems for pallets.

Conveyor equipment for palletized goods can be used both in production and in warehouses with finished products. These systems are used in the following areas: construction, logistics, printing, wholesale, agriculture, special. machinery. Pallet conveyors are compatible with the following types of pallets: EUR 1200x800, FIN 1200x1000 and non-standard pallets.

Conveyor systems for palletized goods are structurally represented by roller and chain conveyors. In turn, roller conveyors can be of the drive and gravity type.

The drive conveyor is a design with movable elements and a power unit for moving palletized goods. Roller drive conveyor is used for large and heavy loads. Gravity storage conveyors often serve as accumulators and operate on the principle of gravity.

The transport line with the use of chain conveyors operates taking into account the cycle of rotation of transport chains. This warehouse conveyor is also designed to move heavy and bulky loads. Drive mechanisms of conveyor lines for pallets are able to withstand not only heavy weight loads, but also work in the temperature range from -30 ° C to +45 ° C. Conveyor equipment capacity up to 200 pallets per hour.

Conveyor systems for boxes and crates.

Conveyor systems for boxes and crates are relevant for automating the process of moving and selecting orders in warehouses with a wide range. Conveyor lines of this type of conveyor systems are represented by roller and belt conveyors. Conveyor line automation is carried out through integration with the WMS system. Maximum performance can be achieved by combining the system with Pick-to-Light.

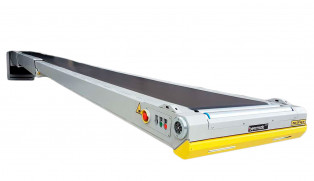

Belt conveyors are of universal importance and can move loads both horizontally and vertically. Most often used for transportation of bulk and small items. You can buy a belt conveyor by calling our specialists.

Conveyor systems for warehouses with a small range of equipment are equipped with roller conveyors of two types: permanent drive and zonal conveyors. The difference between these transport lines is the presence of flow. If your business is characterized by a constant and uniform freight flow, the best solution is a permanent drive conveyor. If the regularity of the flow of goods is absent, you can buy a conveyor zonal type. The presence of buffer zones in this system allows you to efficiently allocate and accumulate reserves. Because the system is powered by motion sensors and powered by low-power motors, the use of this roller conveyor can reduce energy costs.

Technical features of this conveyor system are high speed of order processing, simplicity and flexibility, high accuracy, reduction of labor costs, the ability to operate at low temperatures. If your business is characterized by all these features, you can buy a roller and belt conveyor by contacting the managers of Warehouse Service.

Flexible conveyor systems.

Flexible conveyors are designed to automate the processes of sorting and reloading in retail warehouses. The flexible conveyor is capable to process cargoes not only in trays, boxes, boxes, but also individually in individual packing. The main advantage of the flexible conveyor is the possibility of its placement in a limited space, taking into account structural obstacles: length in the folded state - 2218 mm, in the unfolded state - 8735 mm. Flexible conveyors are driven and gravity. Flexible gravity conveyors are designed using flat rollers. This type of construction helps to save warehouse space

side when assembling the conveyor in the absence of traffic. Flexible drive conveyors do not have such a high degree of compactness, but significantly affect the time limits of cargo transportation by changing the speed of the electric drive. To buy a flexible conveyor and adapt the equipment to your business, you need to contact our specialists.

Spiral conveyors (lifts).

The spiral conveyor is used to increase the degree of automation of technological processes in various fields of economic activity. Conveyor line automation can reach 100% with the complete absence of the human factor. Spiral conveyor for standardized containers and small items is most often used for buffering and sorting of goods. Flexible spiral conveyor, structurally represented by a roller conveyor designed for lowering loads. The spiral conveyor of tape type is capable to carry out transportation of freight in both directions. Flexible spiral conveyor is one of the effective solutions for multi-storey cargo storage. The spiral conveyor on the basis of a roller conveyor is also characterized by budgetaryness owing to lack of the drive and the simplified design of the flexible spiral conveyor.

Our company offers conveyors made in Ukraine and Europe. Sklad Service offers an official warranty from the manufacturers. To place an order and discuss delivery to any locality in Ukraine, contact our specialists.