Lifting tables

Scissor lifts are special equipment used to lift loads in a warehouse, production shop, and car showroom. Stationary lifting tables can be used both indoors and outdoors.

- Load capacity: up to 10 tonnes

- Protection class: IP54

- You can use them in a production facility, warehouse, or service station

- Automatic control system

- Load capacity: 2 to 10 tonnes

- Lifting height is up to 1.6 m

- Rugged construction for high loads

- Protected electrohydraulic unit

- Possibility of installation without a pit

- Load capacity is up to 2 tonnes

- Compact design

- Solid or U-shaped platform

- Fast movement of large pallets

- Load capacity is up to 10 000 kg

- Automated control

- Automated control

Freight elevators are lifting mechanisms that move heavy loads in a vertical position. The hydraulic elevator (elevator lift) is used in warehouses and wholesale bases, in small shops and hypermarkets, in production, in restaurant and automobile spheres. Sometimes elevators are installed in residential buildings.

- Lifting height is up to 4.3 m

- Platform area: 1.35 to 6 m²

- Additional safety systems

- It is powered by the industrial network (380 V, 50 Hz)

- Compact design

- They are designed for lifting passenger cars (up to 2.5 tonnes)

- Easy operation and maintenance

- Lifting height: 3.5 to 7 mm

- Compact size

- Maximum lifting height: 4.3 m

- Load capacity: up to 4 tonnes

- No complex cable structures

- Working height: up to 16 m

- Versatile and practical

- Compact design

- Load capacity: up to 5 tons

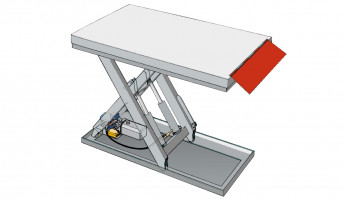

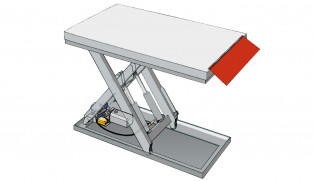

Lifting mechanisms of this type are used where you need to perform a special technical task or handle atypical loads, such as long and bulky. Such tables, in comparison with the classic hydraulic lift, are equipped with additional options necessary for the decision of difficult problems.

- Increased platform length

- Load capacity: up to 8 tonnes

- Lifting height range: 90-200 cm

- Strengthened design

- Easy access to any part of a cargo

- Platform tilt angle: 0-90°

- Lifting height: up to 80 cm

- Maximum load capacity: 800 kg

- Roller elements with 360° rotation angle

- For moving loads weighing up to 7 tonnes

- Lifting levers for container fixing

- Reliable and durable design

The standard equipment of MarcoLift can have a variety of optional devices that allow you to expand the scope of lifting tables, facilitate their operation, increase safety and flexibility.

- For the safety of people and safety of inventory

- Versatility

- Robust design

- 110 cm height

- Availability of a hydraulic drive (in some models)

- Easy operation

- It is divided into sections for ease of use

- Three design options

- Reliable protection against unauthorized access

- Easy installation

- Protection against water, dirt and dust

- Platform with up to 90° tilt angle

- Load capacity is up to 800 kg

- Possibility of individual sizes

- Lifting to a height of up to 80 cm

The company Marco is, without exaggeration, a world leader among enterprises producing hydraulic lifting table and other lifting tables. Specializing only in the production of lifting platforms, "Marco" has gained a lot of experience, has solid knowledge, makes the Swedish manufacturer a reliable and safe supplier capable of solving complex tasks at the highest level.

The company Marco is, without exaggeration, a world leader among enterprises producing hydraulic lifting table and other lifting tables. Specializing only in the production of lifting platforms, "Marco" has gained a lot of experience, has solid knowledge, makes the Swedish manufacturer a reliable and safe supplier capable of solving complex tasks at the highest level.

Advantages of Marco lifting tables

Marco has a wide range of standard models of lifting tables, but, in addition, it has an efficient and flexible production, which allows you to produce lifting tables according to the specific specifics of each customer.

- The hydraulic station of the lift has a transparent tank for convenient visual control of the oil level and is equipped with an overflow valve. The protection class of the electrical component is IP55, if necessary, it can be supplied with a protection class of IP65.

2-3 Lifting tables Marco have scissored arms made of rectangular profiles with a wall thickness of 5 to 10 mm. This design of the scissors gives the lifting tables increased stability under lateral loads and also reduces backlash. Scissor levers are manufactured at an automated production site with high accuracy, which ensures smooth and accurate operation of lifting tables.

- The safety frame made of a solid aluminium profile under the platform guarantees safety for personnel, and also extends the service life of lifting tables. The principle of operation is very simple and reliable: when the frame touches an obstacle, it immediately stops lowering the lifting table.

- Lifting tables are equipped with electric motors manufactured by Sven Hoyer AS, which are protected from overheating and also have an IP 55 protection class.

- Hydraulic table lift Marco has hydraulic cylinders with braking effect (hydraulic damper) to create a smooth lowering of the platform. The cylinders are equipped with safety valves that block operation in case of damage.

- Reliable metal rollers of our own production with a fork attachment device ensure a long service life of the lift.

- The table lift Marco is equipped with restrictive limit switches (except for low-profile tables), with which it is easy to set the maximum height of the lifting table stop.

- For safe maintenance of lifting tables, a safety rod is provided, which will not allow the table to descend during the service inspection.

- The platform is equipped with an adjustable flow valve to ensure smooth lowering regardless of the size of the load.

- For ease of technical maintenance, the Marco lifting table is equipped with easily replaceable axles and inserts.

- Marco lifting platforms have CE certificates of conformity and undergo mandatory individual testing before delivery to the customer. Each of the manufactured tables undergoes tests consisting of more than 25 items before delivery, which confirms the corresponding test report.

Presentation of the Marco company

The group of companies Marco Group is the leader of the European and world market of lifting tables. The company specializes exclusively in the production of lifting tables, has been engaged in this area since 1975 (founded in 1935). The turnover of the Marco Group is over 30 million euros. The structure of the group includes 3 manufacturers of lifting tables: Marco AB (Sweden), Saxon"(England), Hymo AB (Sweden) and the manufacturer of roller shutters – MH Modules (Sweden).

To date, the Marco produces all types of lifting tables for a variety of tasks (loading /unloading, lifting, workplace ergonomics):

- Lifting tables with single scissors;

- High-lift and long-size tables;

- Dock lifting tables;

- Low profile lifting tables;

- Lifting tables-trolleys;

- Car lifting tables;

- Lifting tables with inclined or rotary platform;

- Lifting tables with a roller conveyer for automated lines

- Hydraulic elevators

Tables Marco are supplied with a 2-year warranty on all elements and components. The impeccable quality of the Marco equipment allows it to work without failures for a long time, which is very important for regular operation in a warehouse or production.

All elements of lifting tables are made only by reliable European manufacturers:

- Hydraulics – Bosch Rexroth;

- Electric switches – Telemecanique France (part of the Schneider Electric structure);

- Cylinders – own production of Marco;

- Cylinder seals – SKF Sealing Solutions;

- Electric motors – Sven Hoyer AS.

The company Marco is certified according to the ISO 9001:2008 standard. There is a CE mark on all tables of Marco. Each of the manufactured tables passes tests comprising over 25 items before delivery. Operation parameters and tolerances are checked for compliance and adjusted if necessary.

Lifting tables are designed and manufactured in accordance with the current provisions of the Mechanical Equipment Directive (2006/42/EC), the Low Voltage Devices Directive (2006/95/EC) and the Electromagnetic Compatibility Directive (2004/108/EC), EN 1570 Lifting tables, EN 60204-1 Safety of mechanical equipment – Electrical equipment of machines – General requirements.

All lifting tables Marco are certified according to the Ukrainian standard UkrSEPRO.

Areas of application of lifting tables

Hydraulic lifting tables can be used in all cases where it is necessary to organize the movement of cargo between different levels in height. The most popular options for using scissor tables in the realities of Ukraine:

- For loading and unloading trucks in warehouses, factories, shops, shopping malls. Lifting tables can be used in very different situations:

- - when it is necessary to organize the unloading of goods from the machine to the zero floor level (without a ramp);

- when the ramp is not high, and it is not possible to install an equalizing platform (dock leveller);

- it is possible to install a lifting table for moving cargo with a rocker, and more durable structures (side tables) allow you to drive heavy loading equipment on them;

- lifting the table can be placed indoors or outdoors (environmental protection is provided);

- platforms can be installed in a pit or for unloading machines in a warehouse with a ramp, the table can be placed simply on the ground.

- As an analogue of a freight elevator in any field of activity with a lifting /lowering height of up to 8 meters. High-lift tables at such heights are much more cost-effective than bulky and complex freight elevators. Just like elevators, tables can be installed in the shaft, but they can also be made freestanding. In the latter case, it is desirable to equip the lifting table with a special protective curtain made of PVC.

- To improve the ergonomics of workplaces in production or warehouse, which in turn increases the productivity of working personnel in particular and the efficiency of business.

The European experience is not limited to these 3 cases, lifting tables are used for completely different tasks. The main task is the efficiency of business processes and cost savings provided by the use of lifting platforms.

Why should I buy a lifting table?

A hydraulic lifting table is a necessary and important purchase for every entrepreneur. With this product, you will solve many problems and tasks.

Firstly, the hydraulic lift will give you the opportunity to work both indoors and outdoors. It can also be integrated into a process or production line. At the same time, you can forget about annoying sounds: hydraulic tables are almost silent during the operation. Beside that the tables can be easily dismantled and installed in any other places (an actual offer for those who rent a room or territory).

Secondly, thanks to the thoughtful design of the table, it is possible to load and unload goods from four sides.

Thirdly, the lifting table does not require a large investment during maintenance.

Fourth, such equipment helps to save working space, thanks to the compact size of the table.

It should also be noted that the lifting table helps to save finances. For example, if you need to lift loads to the height of the second or third floors during production or logistics operations, it is better to install a hydraulic lift than an expensive freight elevator. You can buy a removable table in the Sklad Service company