Options for lift tables

- For the safety of people and safety of inventory

- Versatility

- Robust design

- 110 cm height

- Availability of a hydraulic drive (in some models)

- Easy operation

- It is divided into sections for ease of use

- Three design options

- Reliable protection against unauthorized access

- Easy installation

- Protection against water, dirt and dust

- Platform with up to 90° tilt angle

- Load capacity is up to 800 kg

- Possibility of individual sizes

- Lifting to a height of up to 80 cm

Protective fences and gates

When a lifting table is used as a work platform, it is usually required that it be equipped with a protective fence on unprotected sides. It is often supplemented by one or more gates for entry and exit. Usually the gate opens inwards. They must be equipped with an electric closing sensor, which makes it impossible to raise or lower the table when the door is open. The standard design supplied by Marco is a box section fence consisting of two parts and a 150 mm high lower plinth. The total height of the fence is 1100 mm

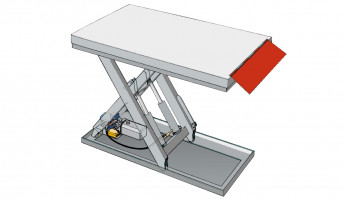

Load hinges

The loading hinge is used as a bridge to bridge the gap between the levels of the lifting table and the loading platform or vehicle. The standard loading folding panel is installed on the outer surface of one of the sides of the lifting table and protrudes about 30-50 mm, depending on the load. The hinge is usually non-automated and can be raised and lowered manually. However, the hinge cover can also have a hydraulic drive. In order to facilitate manual loading / unloading, hinged panels are often divided into sections.

Safety devices

Black folding curtain is the best protection for lifting tables that are exposed to the environment, ie in dirty or humid places, as well as if the lifting table is outdoors. The folding curtain is made of strong folded PVC and is established on all perimeter of a lifting table.

The safety net is used primarily to prevent damage to the lifting table or in the event of a risk of injury. This rugged steel mesh construction is the most reliable protection Marco can offer. However, the grid requires extra space on the frame when the table is in the lowest position.

The black roller blind can be used as an easy way to protect the lever device. The curtain is also often used to hide the lever device, creating a better appearance. The roller blind is made of strong folded PVC and can be installed on each side separately.

Rolling limiter

This equipment prevents the load from rolling off the lifting table during loading. Usually two different designs are used. Both types work so that the anti-roll bar automatically rises around the perimeter of the platform when the lifting table rises from the lower position. In the case of small loads not exceeding 1000 kg, flat metal strips are used as an obstacle. For heavier loads, a more powerful model of a curved plate is used, which is twisted upwards

Wheel frame and loader frame All lifting tables can be equipped with different types of wheel frames. Typically, Marco supplies 2 fixed and 2 movable white nylon wheels with 150 mm diameter brakes. Loading capacity is 1600 kg. For large lifting tables or other applications, Marco may offer special wheels. All lifting tables, which are equipped with wheel frames, have a main frame where the wheels are attached.

The forklift frame is used for all types of lifting tables. As a rule, the lifting table is mounted on a self-supporting main frame. Loading / unloading is possible from both the long and short sides. Usually the frame increases the height of the lifting table by 100 mm. For non-floor-mounted lifting tables, consider how the load will be placed on the lifting table during operation and whether there is a potential risk of tipping over.

PLC system

The PLC system is a computer with removable memory circuits, where you can easily replace existing logic commands. The PLC circuit takes into account timers, calculators, pedometers, shift register, relays, timers, transformers, etc., all in one box. Built-in functions are the main reason why PLCs are used instead of mounting a junction box with these functions from scratch. In general, it is more economical to use a PLC when more than two relays are required for operation. These functions are often used when the lifting table has to be involved in a complex automated production process, or has to be equipped with other functions, such as step travel, intermediate restriction position, etc.

Hydraulic spacer pins

Used when the lifting table needs to be fixed in a certain position in the wall or rack. Unlike the safety stop described below, any form of mechanical and hydraulic deflection of the scissor block is excluded, as the platform is locked by means of rods that protrude from the platform and enter special grooves.

Security stopper

The function of this device is to lock the scissor block in a certain position, often the top. Marco can offer a variety of safety stopper designs. However, all of them function in such a way that the scissor block is fixed mechanically and released by an electromagnet that opens the stopper.