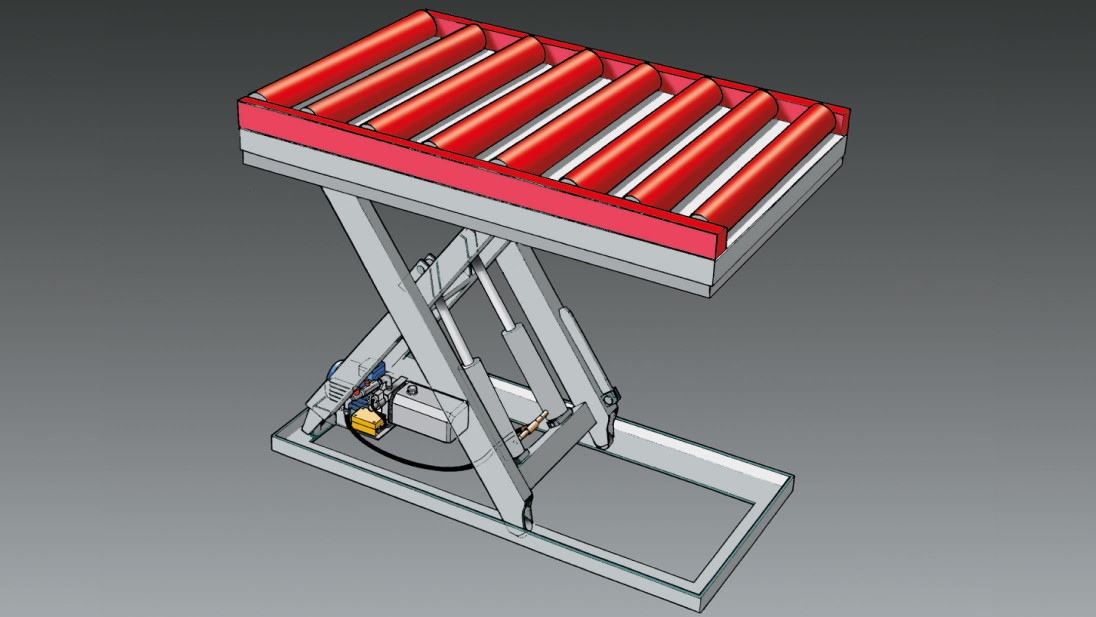

Lift table with rollers

- Fast movement of large pallets

- Load capacity is up to 10 000 kg

- Automated control

- Automated control

Purpose

The lift table with rollers enables loads to be lifted to several metres (depending on the design). With roller elements in the middle, it can be used as part of a conveyor line at the place of production. This design has much in common with roller conveyors and allows arranging a working station for staff engaged in intermediate processing of products and intermediates.

The integrated electric motor allows the load to be conveyed on the conveyor for further transportation. The applications range from the food and light industry to metal machining and mechanical engineering.

Suitable for

- Industrial and warehouse enterprises

- Shopping centres or repair shops

Spheres of activity

-

DIY (construction, repair)

-

Food, beverages

-

Drogerie (cosmetics, household products)

-

Clothing, shoes

-

Pharmaceuticals, medicine

-

Transport, communications, logistics, archives

-

Household appliances, electronics

-

Agro-industrial complex, forestry

-

Cars, special-purpose machineries

-

Finance, insurance

-

Education, culture, printing industry

-

Sports, tourism, entertainment

Description

A lift table is a device for lifting loads, which is carried out by moving the supports of the scissor mechanism using a hydraulic cylinder. The legs are fixed on one side; when the hydraulics are actuated, only their tilt angle will be changed. The supports on the other side of the table move along a horizontal axis. The design is such that when the movable legs are moved, the platform on top is lifted higher or lower.

Lifts with rollers are usually (but not always) installed statically and additional equipment (e.g. a crane beam) is used to move them in the workspace. The table cannot be moved without special equipment due to the weight of more than 1 000 kg. This keeps mobility to a minimum, but the high weight means that the table is virtually immovable and stable in use.

At the same time, there are also models on the market that are equipped with roller wheels. This design allows you to move the table around the work area. To ensure immobility during use, locking mechanisms lock the wheels.

The levers of the scissor mechanism have a rectangular profile. This allows you to evenly distribute the vertical load on all components of the lift and reduce the risk of failure because of increased internal metal stresses.

The upper platform has a segmental structure, which includes roller elements. They are necessary to transfer heavy loads to the conveyor for further processing or storage. For example, if the belt is positioned at a height of up to 1 metre, the table ensures that staff who process products in a particular site will not have to perform works in an unnaturally bent position. This has a positive effect on productivity as well as reduces the risk of occupational injuries. You can use the table as part of a conveyor as well as in other production and storage areas.

The roller elements located on the top platform can be electrically driven by the roller system. This further reduces physical strain on staff. On the other hand, the availability of a drive mechanism requires additional costs for lift table maintenance. However, it pays off quite quickly due to increased labour productivity.

The lift is made of 03X17H14M3 structural steel (European marking is 1.4435 or X2CrNiMo17-12-3). This choice is based on the performance properties of this alloy, which in turn is dictated by its chemical composition. The carbon content of steel is only 0.03%. The alloy has constituents such as chromium (approximately 17%) and nickel (13.5-15%), which increase strength and corrosion resistance, and manganese (1-2%), which increases resistance to shock loads without loss of elasticity.

All metal components are coated with a two-component synthetic epoxy resin and hardeners. This prevents the possibility of corrosion in specific areas of the unit. The resistance to oxidation and rusting is particularly important when the lift is installed in rooms with high humidity. A panel controls the integrated mechanisms (hydraulic cylinder, electric roller conveyor drive, etc.) automatically.

Our range includes Marco lift tables. The head office and main production facilities of this company are located in Engelholm (Sweden). Marco AB has been working in this field for more than 70 years. All products presented in our catalogue necessarily undergo not only European but also Ukrainian certification per DSTU EN 1570: 2013. All mechanisms have a manufacturer warranty for two years.

Specifications

Additional files

Terms of delivery

The price is for the Lift table with rollers in the basic configuration. Without delivery. The exact cost depends on your terms of reference and the current exchange rate. Check with the manager for details.

For bulk orders, individual pricing applies. Call us, we'll agree on a price!

In stock - 1 calendar day

Delivery under the order - from 90 calendar days

Large and non-standard orders are discussed on an individual basis.

The company employs a professional logistics department. We cooperate only with reliable carriers and guarantee high-quality delivery according to the agreed terms. Self-delivery from our warehouse in Kyiv is also possible.

We cooperate with legal entities and individuals, we accept payments in any convenient form.

The amount of the advance payment is agreed on a case-by-case basis.

Lifting tables of both Ukrainian and European production.

The price is for the Lift table with rollers in the basic configuration. Without delivery. The exact cost depends on your terms of reference and the current exchange rate. Check with the manager for details.

For bulk orders, individual pricing applies. Call us, we'll agree on a price!

In stock - 1 calendar day

Delivery under the order - from 90 calendar days

Large and non-standard orders are discussed on an individual basis.

The company employs a professional logistics department. We cooperate only with reliable carriers and guarantee high-quality delivery according to the agreed terms. Self-delivery from our warehouse in Kyiv is also possible.

We cooperate with legal entities and individuals, we accept payments in any convenient form.

The amount of the advance payment is agreed on a case-by-case basis.

Lifting tables of both Ukrainian and European production.