Storage of goods

- Storage utilisation: 80-90%

- A possibility to store a wide range of products

- Relatively quick access to any pallet

It is rational to use them in warehouses with a low turnover ratio of goods when you need access to any pallet. In this case, conventional selective racks are installed on movable platforms that are moved along the guide rails built into the floor. By reducing working passes, we can achieve maximum

- Use of useful warehouse capacity: 90%

- The channel depth is not limited

- Shuttle travel speed: 0.8-1 m/s

A racking system with an automated platform (shuttle) can independently move pallets along the guides. The shuttle is controlled by remote control. Like gravity racks, such systems are designed to store one SKU (stock keeping unit) in a channel. The virtually unlimited channel length and possibilit

- Use of useful warehouse capacity: 70-90%

- The channel depth is not limited

- Shuttle travel speed: 0.8-1 m/s

- Maximum level of automation

The three-dimensional shuttle racking system allows not only move pallets forward or backward within the tier, but also work on the rack in a fully automatic mode. The shuttle has sensors that measure the distance to the nearest obstacle. These, along with specially developed software, allow an auto

- Use of useful warehouse capacity: 75-85%

- Operating temperature: -35 °C to +35 °C

- Work on FIFO and LIFO principles

- Significant acceleration of the warehouse operation

Due to high processing speed and storage density, gravity racks are in demand in FMCG (fast moving consumer goods), in dry and temperature warehouses. Their use not only increases the capacity of the warehouse, but also reduces operating costs. Due to the possibility of working according to F

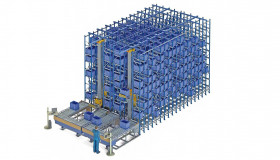

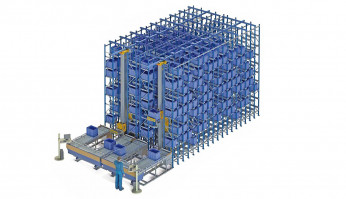

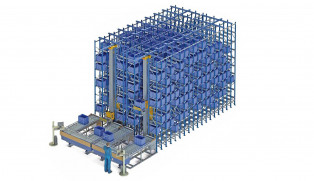

- Operating mode: Continuous

- Accuracy of operations: 99.99%

- Eliminates the loss of time on operations

- Working space height is up to 45 m

AS/RS (automated storage & retrieval system) ensure continuity of operations for transportation, search, placement and unloading of goods. Automatic systems operate in constricted passes at a height of up to 45 m 24 hours per day, 7 days per week, minimizing the impact of human factor and signif

- Speed: 2 to 4 m/s

- High accuracy of operations

- Simplicity and convenience in operation and maintenance

- Safe operation of the rack system

You can use shuttle systems of this category for storage and movement of containers, crates and boxes weighing up to 35 kg. The use of such equipment allows for a significant increase in warehouse productivity due to movement speeds of 2 to 4 m/s. Due to the flexibility of the system for growth, the

- System height: up to 25 m

- Speed: 2 to 4 m/s

- The minimum operating temperature is -35 ° C

- No errors related to the "human factor"

When there is a need to modernize the warehouse and warehouse logistics, the AS/RS system for crates can be an optimal choice. Reaching a height of 25 meters, such racks will ensure the most efficient use of the warehouse area. The AS/RS systems make it possible to process incoming cargo and pick or

- Capacity: up to 80 tons

- Height: 3.3 to 16.1 m

- Maximum efficient use of warehouse space

- Automated control system

Automatic Modula Lift storage systems deliver shelves with goods to the access window on goods-to-person principle. This type of equipment is designed to optimize storage of spare parts, consumer goods, tools, cosmetics, medicines, electrical and electronic components.