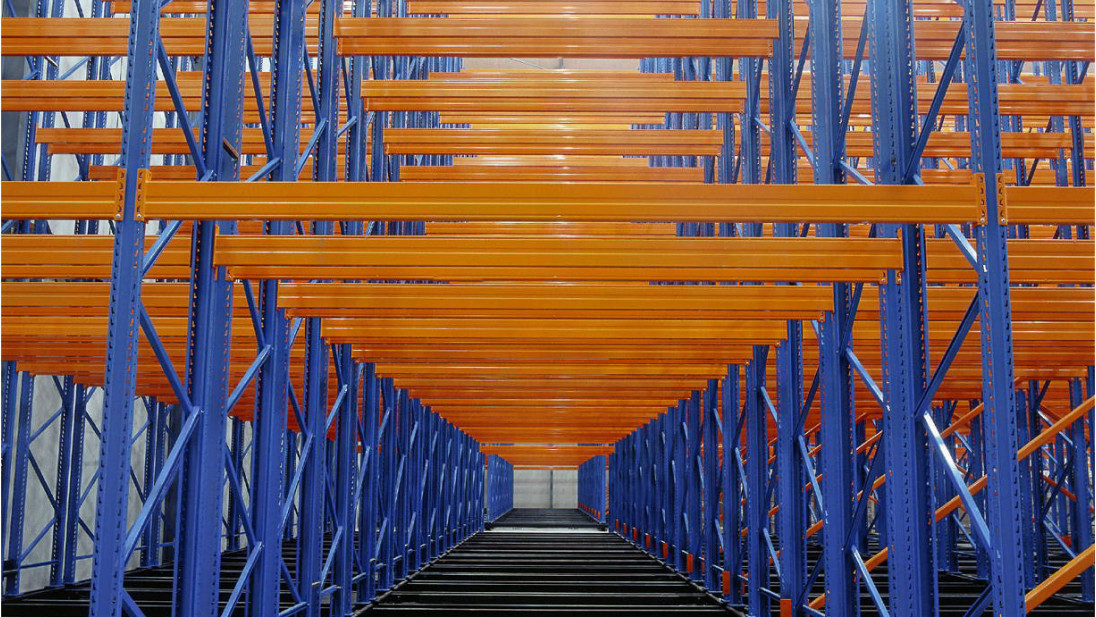

Mobile pallet racking

- Storage utilisation: 80-90%

- A possibility to store a wide range of products

- Relatively quick access to any pallet

Video

Purpose

It is rational to use them in warehouses with a low turnover ratio of goods when you need access to any pallet. In this case, conventional selective racks are installed on movable platforms that are moved along the guide rails built into the floor.

By reducing working passes, we can achieve maximum storage compactness. You can control the rows automatically or manually. A large number of sensors ensure complete safety for staff.

Suitable for

- 1200x800 EUR pallets

- 1200x1000 FIN pallets

- Non-standard pallets

- Barrels

- Containers

Description

Mobile selective racks are classic designs for storing pallets mounted on movable bases that move along rails built into the floor in advance. Thus, leaving only one working pass and moving racks to the left or right, you can receive relatively quick access to any row and a specific storage bin.

It is the accessibility of any pallet and the high storage density at the same time are the main advantages of these racks. Therefore, mobile racks can serve as an excellent solution when it is necessary to place a wide range of goods compactly on a limited area or when the task is to optimize the warehouse area already in the stage of project design.

It is not surprising that these systems have proved their worth in Europe, particularly in low-temperature warehouses, as the cost of building and maintaining freezers is high.

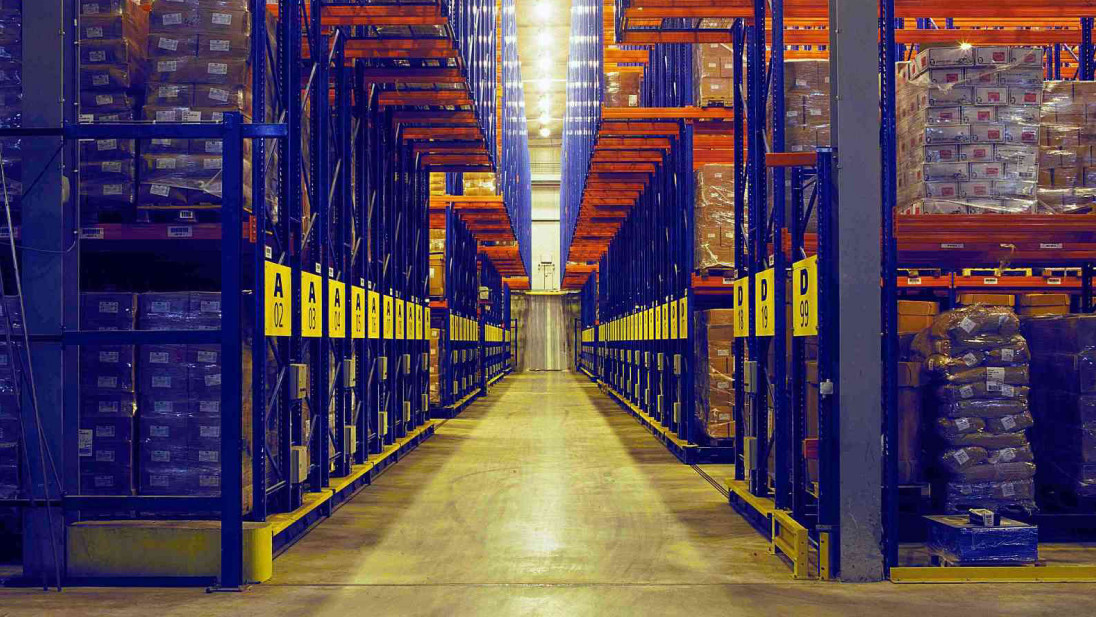

Mobile racks are controlled through remote control, which the warehouse equipment operator keeps with him/her or via buttons on the ends of the racking rows. Working with a mobile rack is completely safe due to a host of photodetectors and an automatic control system. The program will not allow you to close the working corridor while a forklift or a person is inside the structure.

Although mobile racks offer lower turnover capacity than stationary racks, a row displacement speed of 4-5 m/min is enough to enter a new corridor without much delay after completing the last task.

As to the weight and dimensional parameters of cargo, mobile racks do not impose any significant restrictions. The length of a single rack row is up to 50 meters, and the total load on one mobile base (double row) can reach 400 tons. This is sufficient for most applications.

Specifications

Additional files

Projects

for your tasks

With 18 years of experience, we have created a list of effective solutions to problems in any area of business.

We will help to create the most effective structure for your tasks.

Terms of delivery

The price is indicated for mobile racks for europallets in the basic volume. Delivery and installation are not included in the cost of construction. The exact cost of mobile pallet racks depends on your technical task and the current exchange rate. Check with the managers for details.

Individual pricing applies to bulk orders. Call, we will agree on the price!

If in stock – 3 calendar days

Delivery under the order – from 35 calendar days

Large and non-standard orders are discussed individually.

The company has a professional logistics department. We cooperate only with reliable carriers and guarantee quality delivery according to the stipulated terms. Self-pickup from our warehouse in Kyiv is also possible.

We cooperate with legal entities and individuals, we accept payments in any convenient form.

The amount of prepayment is agreed in each case.

Stow is one of the world leaders in the production of static and dynamic storage racks. Starting in 1977, today Stow is a benchmark of world standards in the field of innovation, reliability and manufacturability of storage rack systems.

All elements of racks are made on fully automated production that reduces prime cost and terms of delivery of racks, and also guarantees invariable quality and accuracy of all details.

The price is indicated for mobile racks for europallets in the basic volume. Delivery and installation are not included in the cost of construction. The exact cost of mobile pallet racks depends on your technical task and the current exchange rate. Check with the managers for details.

Individual pricing applies to bulk orders. Call, we will agree on the price!

If in stock – 3 calendar days

Delivery under the order – from 35 calendar days

Large and non-standard orders are discussed individually.

The company has a professional logistics department. We cooperate only with reliable carriers and guarantee quality delivery according to the stipulated terms. Self-pickup from our warehouse in Kyiv is also possible.

We cooperate with legal entities and individuals, we accept payments in any convenient form.

The amount of prepayment is agreed in each case.

Stow is one of the world leaders in the production of static and dynamic storage racks. Starting in 1977, today Stow is a benchmark of world standards in the field of innovation, reliability and manufacturability of storage rack systems.

All elements of racks are made on fully automated production that reduces prime cost and terms of delivery of racks, and also guarantees invariable quality and accuracy of all details.