Shipment

- Use of useful warehouse capacity: 75-85%

- Operating temperature: -35 °C to +35 °C

- Work on FIFO and LIFO principles

- Significant acceleration of the warehouse operation

Due to high processing speed and storage density, gravity racks are in demand in FMCG (fast moving consumer goods), in dry and temperature warehouses. Their use not only increases the capacity of the warehouse, but also reduces operating costs. Due to the possibility of working according to F

- Automation of transportation of finished products and raw materials

- They are suitable for "cold" warehouses and refrigerators

- They are compatible with pallets of all sizes

- Carrying capacity is up to 2000 kg

You can use conveyor systems mainly to transport palletised goods between different sites of a company: from the raw material warehouse to production, from production to the finished product warehouse, and between individual production departments. Where goods are moving along a fixed route and the

- They facilitate loading and unloading of goods

- They extend two-four times when unfolded

- Maximum load: 80 kg/m

- High mobility and flexibility of use

Flexible conveyors are widely used for transhipment and sorting of goods. By being positioned between the loading area and the vehicle, they facilitate the placement of cargo in vehicles. The flexibility of the scissor system allows you to install the conveyor in various configurations and adjust it

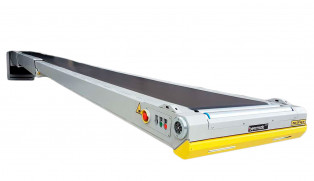

- They accelerate loading and unloading operations

- They easily adapt to the required length and height

- Maximum extension: up to 18 m

- The speed of cargo movement is 0.8 m/s

You can use telescopic conveyors to simplify loading and unloading of goods in boxes or crates. Their use makes it possible to speed up the movement of cargo from the warehouse directly to the place of placement in the truck, leaving only the stacking functions to loaders. As the vehicle is loaded,