Gravity flow racks

- Storage utilisation: 75-85%

- Operating temperature: -20°C to +35°C

- Work on the FIFO and LIFO principles (at low channel depth)

- Significant speedup of warehouse operation, which is especially advantageous in temperature controlled warehouses

Video

Purpose

Due to high processing speed and storage density, gravity flow racks are in demand in the logistics of Fast-moving consumer goods), in dry and temperature controlled warehouses. Their use not only increases the capacity of the warehouse but also reduces operating costs.

Working on the FIFO principle (first-in, first-out), they are actively used in areas where the ease of tracking the shelf life of products is important. Unlike other storage systems, almost any type of loader can handle gravity flow racks.

Suitable for

- 1200x800 EUR pallets

- 1200x1000 FIN pallets

Description

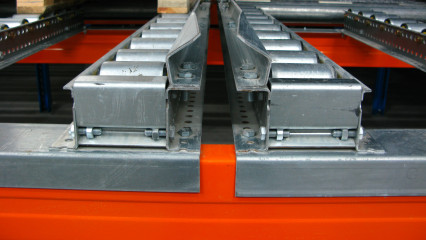

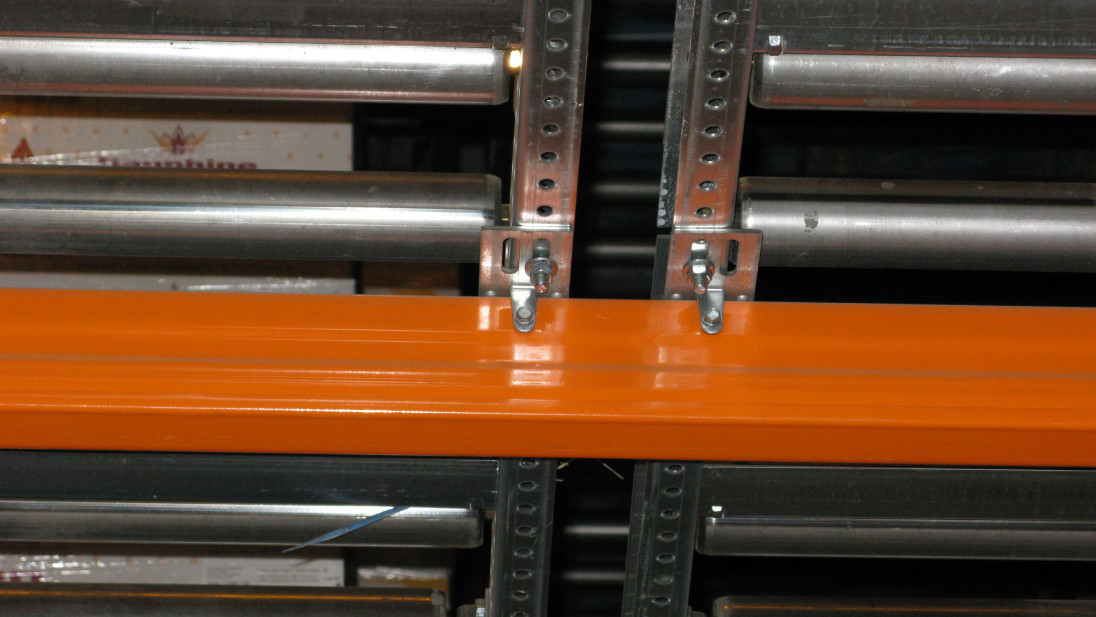

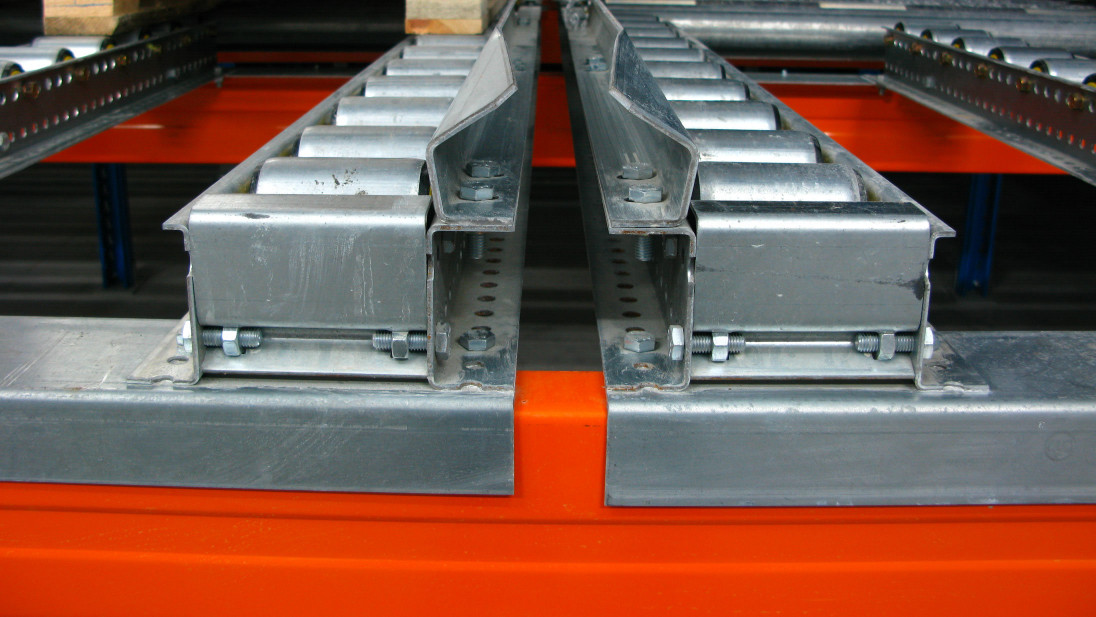

Gravity flow racks can be considered an automated version of Drive-in pallet racking since pallets with cargo are also loaded into the depth of the racking system. Roller conveyors installed at an angle of 4 degrees are used here as support guides. Such racks are called gravity flow racks because a pallet with cargo under its gravity moves independently along roller guides.

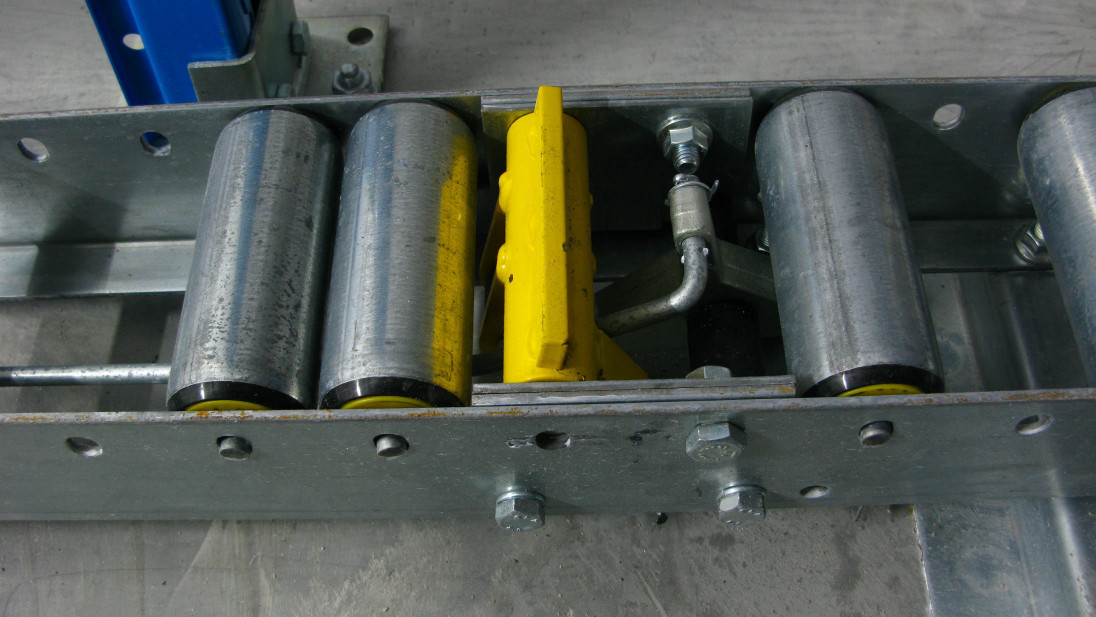

To ensure constant and safe movement of the pallet along the roller conveyor, braking rollers are fitted at every meter , which revolves in the opposite direction and prevents the pallet from travelling too fast. The pallet, which stands first in the unloading area, is separated from the rest of the pallets by a separator, so you can easily remove it from the channel.

Safe operation with such systems places high demands on the geometry and quality of pallets. As a rule, there are no problems with the directness of pallets. However, for additional safety, it is possible to install roller stops that hold the pallet with cargo in the correct position.

Gravity flow racks are used mainly on the FIFO principle (first-in, first-out) when the first loaded pallet will be unloaded first. This makes it easy to control many products with a limited shelf life, preventing the shipment of fresher goods before their turn.

It is important to understand that the rack channel is designed to store one SKU since there is only access to the last pallet in the unloading area. Therefore, such a system is suitable for storing a relatively small range of goods.

With a channel depth of up to six pallets, you can use the LIFO principle. In this case, loading equipment will have to carefully push the pallets placed on the rack with the pallet it is currently installing.

Since the warehouse equipment does not drive into the rack, this saves time and increases operational safety. Unlike other storage systems, almost any type of loader can handle gravity flow racks.

Specifications

Additional files

Projects

for your tasks

With 18 years of experience, we have created a list of effective solutions to problems in any area of business.

We will help to create the most effective structure for your tasks.

Terms of delivery

The price is indicated for gravity racks for Europallets in the basic volume. Delivery and installation are not included in the cost of construction. The exact cost of pallet racks depends on your technical task and the current exchange rate. Check with the managers for details.

Individual pricing applies to bulk orders. Call, we will agree on the price!

If in stock – 3 calendar days

Delivery under the order – from 35 calendar days

Large and non-standard orders are discussed individually.

The company has a professional logistics department. We cooperate only with reliable carriers and guarantee quality delivery according to the stipulated terms. Self-pickup from our warehouse in Kyiv is also possible.

We cooperate with legal entities and individuals, we accept payments in any convenient form.

The amount of prepayment is agreed in each case.

Stow is one of the world leaders in the production of static and dynamic storage racks. Starting in 1977, today Stow is a benchmark of world standards in the field of innovation, reliability and manufacturability of storage rack systems.

All elements of racks are made on fully automated production that reduces prime cost and terms of delivery of racks, and also guarantees invariable quality and accuracy of all details.

The price is indicated for gravity racks for Europallets in the basic volume. Delivery and installation are not included in the cost of construction. The exact cost of pallet racks depends on your technical task and the current exchange rate. Check with the managers for details.

Individual pricing applies to bulk orders. Call, we will agree on the price!

If in stock – 3 calendar days

Delivery under the order – from 35 calendar days

Large and non-standard orders are discussed individually.

The company has a professional logistics department. We cooperate only with reliable carriers and guarantee quality delivery according to the stipulated terms. Self-pickup from our warehouse in Kyiv is also possible.

We cooperate with legal entities and individuals, we accept payments in any convenient form.

The amount of prepayment is agreed in each case.

Stow is one of the world leaders in the production of static and dynamic storage racks. Starting in 1977, today Stow is a benchmark of world standards in the field of innovation, reliability and manufacturability of storage rack systems.

All elements of racks are made on fully automated production that reduces prime cost and terms of delivery of racks, and also guarantees invariable quality and accuracy of all details.