Sandwich panels warehouses

- The width of the warehouse is up to 40 meters

- High energy efficiency

- Does not require commissioning

- It can be used in the pharmaceutical field

Video

Purpose

The high energy efficiency of sandwich panels allows them to be used as a warm warehouse, production, store or administrative room. Without requiring significant heating in winter, warehouses with a double PVC roof keep cool better in the summer heat.

Designed for storing cargo of various types and methods of unloading / loading. Due to the overall dimensions (wall height - up to 8 m), it is possible to install a wide range of shelving and conveyor systems, use of warehouse equipment. Sandwich panel buildings are designed for long-term operation as a permanent warehouse, but can be easily disassembled and installed in a new location.

Suitable for

- Warm warehouses

- Production facilities

- Military bases

- Licensed warehouses

- Animal husbandry

Description

Sandwich panel warehouses are a type of tent prefabricated buildings made of modular aluminium and steel structures. The use of sandwich panels for walls, and for the roof of a double PVC sheet, makes such rooms energy efficient and warm.

Sandwich panel is a well-known and widespread material not only in Ukraine, it consists of two sheets of rigid base and insulation between them. Polyurethane foam, mineral wool or expanded polystyrene is used as insulation. Most often, modular warehouses are equipped with sandwich panels with a thickness of 60 - 80 mm, although it is possible to install a sandwich with a thickness of 100 or 120 mm to increase thermal insulation characteristics.

Installation of a warehouse made of sandwich panels can be carried out on any solid surface: slab, crushed stone, concrete, asphalt, foundation. Such warehouses are an optimal alternative to capital construction, they do not require a permit for commissioning. The possibility of licensing the premises of this technology allows it to be used in the pharmaceutical field.

The modular and thoughtful design of the building elements allows you to complete the installation in the shortest possible time. For example, the installation of a typical 1,000 square meter prefab warehouse will take only three weeks.

The absence of columns inside the building, ample opportunities in overall dimensions, the ability to withstand high loads (wind, snow), makes these warehouses the optimal solution for a wide range of tasks, which can also be operated year-round in all weather conditions.

The angle of inclination of the roof is 22 degrees, which allows the water to flow freely. The optimal angle is selected taking into account the climatic features of the region.

Possible additional options:

lighting, heating (oil, electric stoves, heaters, other solutions), air conditioning and forced ventilation, double-glazed windows, doors, gates of various types and sizes.

Sklad Service team helps in selecting the necessary materials according to the scope of use of tent warehouses, delivers to the facility, installation / dismantling, provides warranty and post-warranty service, conducts routine and unscheduled repairs.

Warehouses made of sandwich panels are manufactured on modern equipment based on the ISO 9001 quality management system. The official warranty from the manufacturer is 3 years. At the same time, the reliability and strength of the components ensures a service life of at least 50 years.

Specifications

Projects

Terms of delivery

The price is indicated for one m2. No delivery or installation. The exact cost will depend on your technical specifications and the current exchange rate. The minimum order for calculation is 300 m2. Check with the manager for details. Call us, we'll agree on a price!

High expertise in prefabricated buildings (more than 19 years of experience) allows us to implement a turnkey project in the shortest possible time. Warehouse in less than two months - these are real cases.

We cooperate with legal entities and individuals, we accept payments in any convenient form.

The amount of prepayment is agreed in each case.

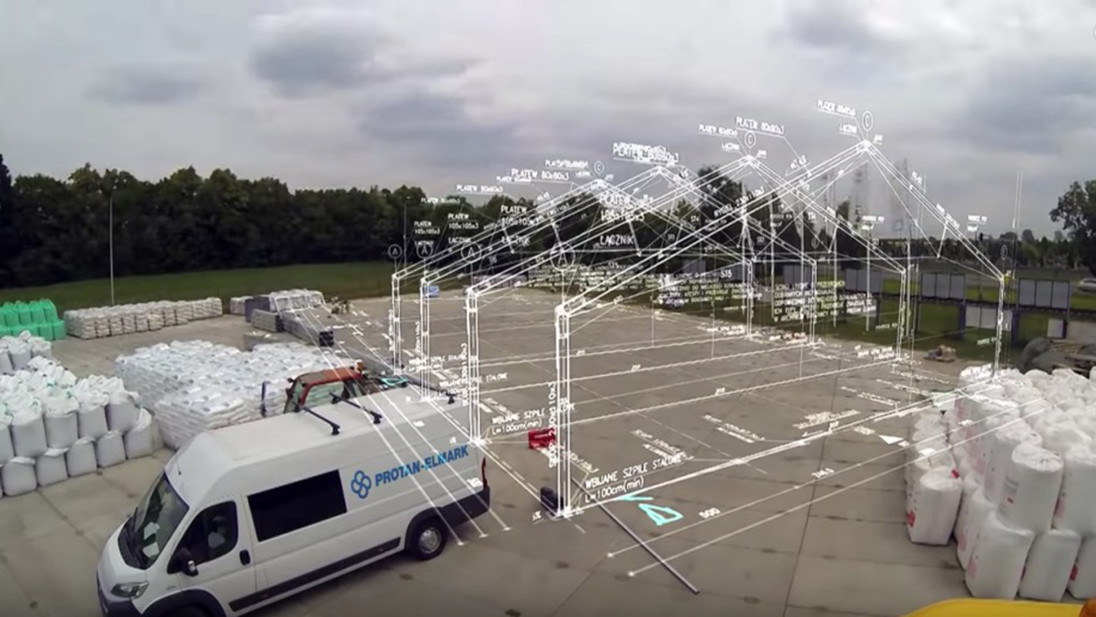

In August 2008, the Norwegian company Protan AS, which has been on the market since 1939 and produces high-quality PVC materials, merged with the Polish company Elmark Hale, which has been producing large awning halls since 1989. Thanks to many years of experience, an exceptional offer has been created in the segment of buildings that are quickly erected on the basis of lightweight aluminum structures.

The price is indicated for one m2. No delivery or installation. The exact cost will depend on your technical specifications and the current exchange rate. The minimum order for calculation is 300 m2. Check with the manager for details. Call us, we'll agree on a price!

High expertise in prefabricated buildings (more than 19 years of experience) allows us to implement a turnkey project in the shortest possible time. Warehouse in less than two months - these are real cases.

We cooperate with legal entities and individuals, we accept payments in any convenient form.

The amount of prepayment is agreed in each case.

In August 2008, the Norwegian company Protan AS, which has been on the market since 1939 and produces high-quality PVC materials, merged with the Polish company Elmark Hale, which has been producing large awning halls since 1989. Thanks to many years of experience, an exceptional offer has been created in the segment of buildings that are quickly erected on the basis of lightweight aluminum structures.

Frequently asked questions

Быстровозводимые здания из сендвич панелей можно использовать как теплый склад, производство, магазин или административное помещение.

Монтаж склада из сэндвич-панелей можно производить на любой твердой поверхности: грунт, плита, щебень, бетон, асфальт, фундамент. Быстровозводимые здания из сэндвич панелей – оптимальная альтернатива капитальному строительству, они не требуют разрешения для ввода в эксплуатацию.