Production areas (production bay)

- Optimization of production costs

- Maximum free space inside

- Unlimited room length

Video

Purpose

Prefabricated buildings can be effectively used for production areas and bays. Prefabricated buildings do not require a permit for commissioning, are manufactured and delivered in 1 - 3 months, are installed in 1 - 2 days. As a result, fast implementation and low cost of technology, in comparison with capital construction, optimize project costs, allowing to achieve a competitive price of the final product.

The possibility of installing strong walls made of corrugated board or sandwich panels, as well as the integration of heating, water systems, ventilation, etc. makes such rooms an adequate solution for most production tasks. After all, in some cases, capital-built buildings are excessively material-intensive, which is not fully used in practice and does not justify high investment in construction.

Suitable for

- Service stations

- Production lines

- Warehouses

- Utility rooms

Spheres of activity

-

DIY (construction, repair)

-

Food, beverages

-

Drogerie (cosmetics, household products)

-

Clothing, shoes

-

Pharmaceuticals, medicine

-

Transport, communications, logistics, archives

-

Household appliances, electronics

-

Agro-industrial complex, forestry

-

Cars, special-purpose machineries

-

Public utilities

-

Finance, insurance

-

Education, culture, printing industry

Description

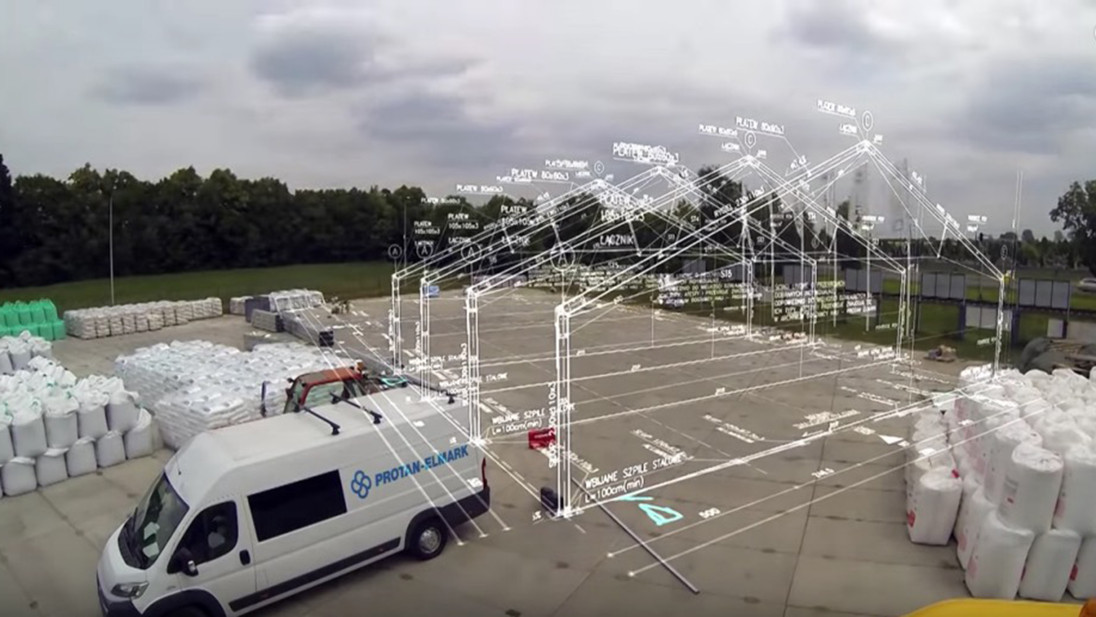

Prefabricated buildings for production facilities and production bays are an excellent alternative to structures with a steel frame or brick buildings. They consist of steel/aluminium beams and trusses covered with one or two layers of PVC fabric (awning).

Within 1-2 months, you can deploy a new or increase the existing production space. Without requiring commissioning, this technology will allow you to quickly solve a business problem, which will ultimately accelerate the return on investment and increase the profitability of the project.

The optimal width of the structure is 25 - 40 meters. At the same time, there are absolutely no support columns inside the room, which simplifies the placement of equipment and the movement of loading equipment.

If it is necessary to increase the width of the room, the neighbouring building is attached next to it, without installing a common wall, only columns with a step of 3 - 5 meters. As a rule, production lines are large, and such modular warehouses have no length restrictions.

The frame materials are mainly anodized aluminium (service life of 50 years, resistant to corrosion), to a lesser extent profiled steel, specially designed for areas with extreme weather conditions.

A common and basic material for walls and roofs is PVC fabric, a lightweight and durable material that provides effective protection from rain and wind. It transmits sunlight, providing illumination of the room during the daytime, which will reduce operating costs.

If the room is planned to be used for a long time on one site, and it is necessary to provide effective heating in winter, it is better to consider the following wall options:

Profiled flooring – single-layer steel walls (T-18, T-35), which provide strength and prevent malicious intruders into the room.

Insulated sandwich panels (60 - 120 mm thick) are the most energy-efficient option, combined with heating systems (oil, electric stoves, heaters, other solutions) will create a comfortable indoor environment, no different from warm capital construction.

To increase the thermal insulation of the roof, you can also use additional options:

PVC double + Black Out – Black Out material is glued between two layers of PVC with the application of British reflective foil. Thanks to this coating, thermal insulation is provided in winter and the preservation of coolness on hot days.

Inflatable PVC is a two–layer PVC into which air is pumped, and a constant pressure is maintained with the help of a pump. This option is the most heat-saving and is suitable for effective heat preservation even in harsh winter conditions.

A huge advantage of prefabricated tent buildings is the possibility of multiple installation-dismantling and relocation. Such work takes place easily and quickly, and the components and materials of the room themselves do not lose their qualities. This allows you to use one building at different locations of the enterprise or, if necessary, easily sell it for installation in a new location.

Production areas often require zoning of the premises depending on the operations. For this purpose, it is possible to install additional options: windows, doors and gates, heating systems, forced ventilation and air conditioning.

Windows can be installed both in the form of transparent inserts and solid full-fledged windows (in the case of sandwich panel walls). Doors and gates can be made in the form of sliding, roller, casement and hinged. Their mixing is possible depending on the zoning of the room.

Sklad Service team helps in selecting the necessary materials according to the scope of use of tent warehouses, delivers to the facility, installation / dismantling, provides warranty and post-warranty service, conducts routine and unscheduled repairs.

Modular prefabricated premises are manufactured using modern equipment based on the ISO 9001 quality management system. The official warranty from the manufacturer is 2 years. At the same time, the reliability and strength of the components ensures a service life of at least 50 years.

Specifications

Projects

Terms of delivery

The price of this type of product depends on the exchange rate, may be higher or lower, it is worth clarifying. The price also depends on the set of additional components you choose and the color of the product.

We draw your attention to the fact that prices are calculated individually depending on the volume of the order. There is a flexible system of discounts for wholesale buyers.

Large and non-standard orders are discussed individually.

The company has a professional logistics department. We cooperate only with reliable carriers and guarantee quality delivery according to the stipulated terms. Self-pickup from our warehouse in Kyiv is also possible.

We cooperate with legal entities and individuals, we accept payments in any convenient form.

The amount of prepayment is agreed in each case.

In August 2008, the Norwegian company Protan AS, which has been on the market since 1939 and produces high-quality PVC materials, merged with the Polish company Elmark Hale, which has been producing large awning halls since 1989. Thanks to many years of experience, an exceptional offer has been created in the segment of buildings that are quickly erected on the basis of lightweight aluminum structures.

The price of this type of product depends on the exchange rate, may be higher or lower, it is worth clarifying. The price also depends on the set of additional components you choose and the color of the product.

We draw your attention to the fact that prices are calculated individually depending on the volume of the order. There is a flexible system of discounts for wholesale buyers.

Large and non-standard orders are discussed individually.

The company has a professional logistics department. We cooperate only with reliable carriers and guarantee quality delivery according to the stipulated terms. Self-pickup from our warehouse in Kyiv is also possible.

We cooperate with legal entities and individuals, we accept payments in any convenient form.

The amount of prepayment is agreed in each case.

In August 2008, the Norwegian company Protan AS, which has been on the market since 1939 and produces high-quality PVC materials, merged with the Polish company Elmark Hale, which has been producing large awning halls since 1989. Thanks to many years of experience, an exceptional offer has been created in the segment of buildings that are quickly erected on the basis of lightweight aluminum structures.